Researchers from Sandia National Laboratories (SNL) and Texas A&M University in the US have observed cracks in a metal becoming shorter. The unexpected finding – cracks normally grow longer – upends theories of fracture in metals and could help in the design of materials that “heal” their own internal damage.

When metals repeatedly undergo stresses and strains, microscopic cracks begin to form. These cracks are a type of fatigue damage, and over time, they grow and spread until they eventually cause the structure to fail – often unpredictably.

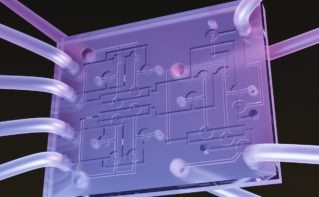

Such growth had been assumed to be irreversible, but researchers led by SNL materials scientist and engineer Brad Boyce found that this isn’t necessarily true. In their study, they used a specially modified electron microscope that allowed them to strain nanoscale samples of platinum repeatedly while observing what happens inside them. As expected, they saw nanoscale fatigue cracks appearing early on in the experiment. Unexpectedly, however, they also saw the ends of cracks fusing back together roughly 40 minutes later.

“Cracks were only ever expected to get bigger, not smaller,” Boyce says. “Even some of the basic equations we use to describe crack growth preclude the possibility of such healing processes.”

Crack flank cold welding

The SNL team wasn’t purposefully looking for this effect when the experiment began, but after observing it, members identified the damage reversal process, or “self-healing”, as a form of cold welding that occurs at the flanks of cracks. This effect is induced by a combination of local stress and grain boundary migration, and Michael Demkowicz, a professor of materials science and engineering at Texas A&M, predicted in 2013 that it was possible.

Uncovering the tiny defects that make materials fail

“When the microstructure of the material changes, it can push together the opposing forces of a crack,” Demkowicz explains. “If those faces are clean, they can bond and ‘heal’ via cold welding.”

While researchers have fabricated self-healing materials before, these have mainly been made of plastic, not metal. Demkowicz, however, calculated that under certain conditions, metals should be able to weld shut cracks created by fatigue damage. “It proved difficult to come up with an experiment that could test my prediction, but the SNL researchers, who were in fact working on understanding general damage evolution, serendipitously ended up observing the process that I’d theorized.”

In the near term, Demkowicz tells Physics World that the team’s findings will help improve theories of fractures in metals. In the longer term, they might lead to new strategies for designing metals that resist damage.

For this study, which is detailed in Nature, the researchers performed their measurements in a vacuum, so it is unclear whether the crack healing can also occur in air. The researchers would now like to find out if this is possible.