Researchers attempting to build the next generation of quantum computers are pushing the boundaries of what can be achieved with current experimental technologies. One of the challenges is testing the behaviour of a complex quantum system when it is sealed inside a cryogenic system cooled close to absolute zero. Not only does it make it difficult to assemble, adjust and maintain the components and wiring needed for each experiment, but it can also place practical limits on the size of the quantum system that can be measured.

Finnish company Bluefors has dedicated itself to making life easier for researchers working with such complex experimental systems. Founded in 2008 by two low-temperature physicists, Rob Blaauwgeers and Pieter Vorselman, the company has perfected a series of cryogenic systems that combine high performance with reliability and ease-of-use.

“Many new technologies, including quantum computing, require a controlled measurement environment at temperatures close to absolute zero,” says David Gunnarsson, the company’s chief sales officer. “Cryogenic systems have traditionally been difficult to use and maintain, and our aim is to eliminate those obstacles and enable our users to focus on being creative in their research.”

Bluefors has built its business from developing cryogen-free dilution refrigerators, which avoid the need for liquid helium as a pre-cooling agent. These so-called “dry” systems – which over the last 10 years have become the technology of choice for low-temperature research – make it easier to install samples into the chamber, offer more space for the experimental load, and enable more automation because they require less hands-on attention than previous “wet” systems.

The Bluefors team has exploited their knowledge of the underlying cryogenics technology to build commercial systems that can accommodate large experimental assemblies and can be operated by non-specialists. “Researchers who installed our equipment in their labs realized that everything was so much easier,” comments Gunnarsson, who believes that ongoing improvements in these cryogenic systems have been a crucial enabler for the upswell of commercial interest in quantum computing. “Quantum technology and the development of new cryogenic systems has gone hand in hand, and has driven both technologies forward,” he says.

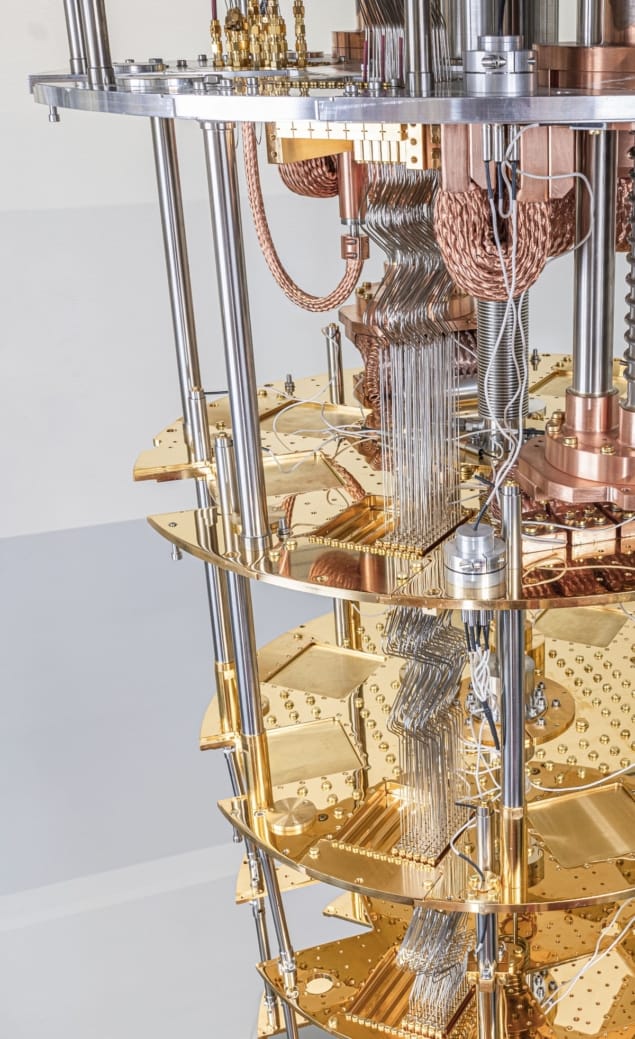

Bluefors’ strong links with the scientific community has been the lifeblood that has driven continued innovation. A few years ago, in the first of a series of major upgrades, the company equipped its high-performance XLD cryostat with a side-loading system that makes it simpler and more efficient for scientists to design and build their experiments.

“Normally the measurement infrastructure would be assembled inside the cryogenic system, but this restricts access to the components and wiring,” explains Gunnarsson. “Dilution refrigerators are so tall that ladders are needed to reach all the different levels, making it difficult to assemble the measurement equipment without making mistakes.”

In contrast, the side-loading system allows the experimental components and wiring to be fully assembled on the lab bench, and then transferred into the cryogenic system when it is brought up to room temperature. Such an approach allows researchers to easily check that the connections are attached properly, reducing the need for further adjustments when the experiment is installed in the cryostat.

Researchers who installed our equipment in their labs realized that everything was so much easier

David Gunnarsson

The XLD system comes with six side-loading ports, each of which can accommodate the measurement infrastructure for a different experiment. “Many of our customers want to buy one big fridge that can be used for many users performing different experiments at the same time,” says Gunnarsson. “Experiments can be prepared when the system is cold, and then when it is brought up to room temperature the experiments can be changed at the same time. This allows the system to be cooled down more quickly after the maintenance.”

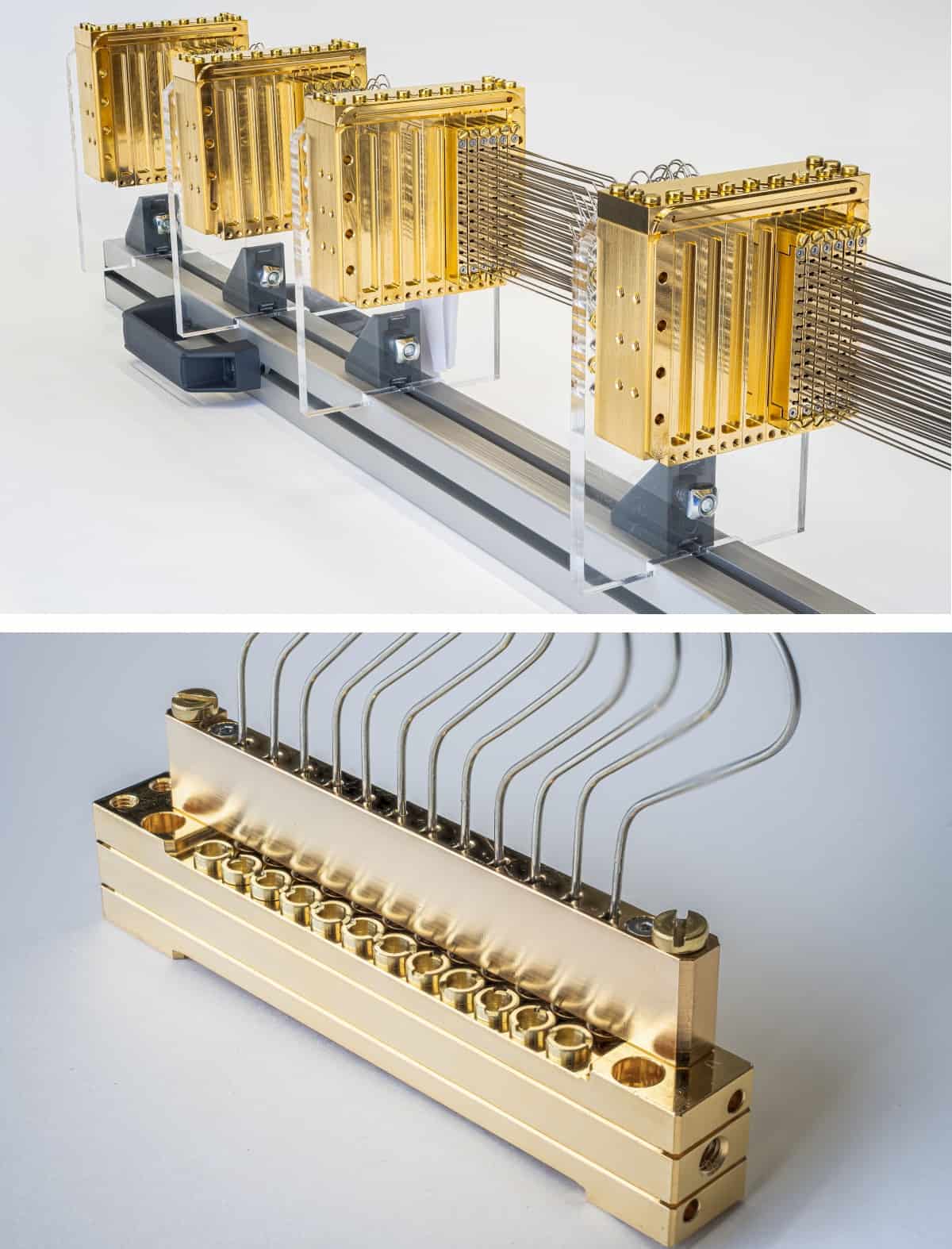

Bluefors has built on this innovation by introducing a modular system that provides a standard way for loading experiments into the cryostat. The components and wiring are assembled inside a module with a standard form factor that simply snaps into the side-loading ports, allowing for quick maintenance of complex assemblies. “The modular system makes it possible to increase the number of wires and components in the system, allows rapid testing and troubleshooting, and ensures quick turn-around for busy multi-user environments,” says Gunnarsson. “All this is done without compromising the thermal properties and strengths of the cryogenic system, which still keeps the operating temperature at millikelvin temperatures.”

Bluefors developed this modular form factor under the framework of the OpenSuperQ project, part of Europe’s Quantum Flagship programme. “It is an open standard that we hope component suppliers will adopt when developing new cryogenic measurement devices,” comments Gunnarsson. “It will make cryogenics a more robust technology, and a standards-based approach should encourage the development of more commercial applications for quantum systems.”

The latest addition to Bluefors’ modular system is the option for high-density wiring, which has become increasingly important as scientists seek to increase the number of qubits in their quantum computing systems. “Until now it has been necessary to attach each component one wire at a time, which is fine for small-scale systems,” says Gunnarsson. “But the footprint of the cryogenic system gets used up quickly as more quantum elements are added, and assembly, installation and maintenance become much more difficult and time-consuming for large numbers of wires and components.”

Gunnarsson explains that most experiments in cryogenic systems require several continuous control wires from room temperature down to the lowest temperature in the cryostat. Typically, two or three wires might be needed to control and measure each quantum element – depending on the experimental architecture that has been deployed. The challenge for researchers is how to scale up from lab-scale demonstrations with just a few qubits to more useful quantum computers that will need hundreds of quantum elements.

To address this need, the high-density interface introduced by Bluefors allows researchers to build experiments with more than 1000 high-frequency lines in one system. Making sure that each wire is connected properly is more difficult with such a large number of control lines, so the interface has been designed to allow the wires to be installed in blocks of 12.

The interface exploits standard connectors and coaxial cables for the wiring, and the attenuators have been embedded in a single block that fits into the modular system. Meanwhile, the modular form factor also allows the use of custom components with multiple high-density channels, such as amplifiers, filters and attenuators.

Further into the future, quantum computers are likely to need millions of qubits. It would be impossible to connect that many cables into a cryogenic system, and Gunnarsson says that the research community is still working to develop new technical solutions, such as cold logic and wire multiplexing. “Bluefors is active here and the modular concept will support these developments,” he says.

“Our modular concept makes it possible, now and in the future, to easily maintain a large cryogenic measurement infrastructure,” continues Gunnarsson. “Cryogenics should not be an obstacle that stops anyone from doing an experiment or developing an application; the measurement infrastructure should be readily available so researchers can focus on making their experiment.”