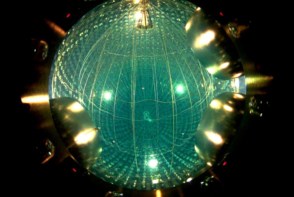

Less, it seems, is always more in the rarefied world of extreme-high-vacuum (XHV) systems. Operating at pressures of 10–10 Pa and lower, XHV is a core enabling technology of many big-science programmes – think the Large Hadron Collider at CERN or the LIGO gravitational wave observatory. At the other end of the scale, XHV underpins all manner of small-science endeavours – from R&D on quantum computing to the fabrication of next-generation semiconductor chips. Despite such versatility, significant gaps remain when it comes to understanding, comparing and benchmarking the technical specifications and performance of XHV chambers from different manufacturers.

Fundamental to the successful operation of any XHV system is a chamber with ultralow outgassing rates, such that gases (typically hydrogen) dissolved in the bulk of the chamber material are removed or prevented from leaving the material surface. Trouble is, commercial vendors rarely report or specify outgassing rates for their XHV chambers. When they do, it is often tricky to compare the experimental data because different studies use different chamber geometries, environments, and sometimes poorly defined or poorly implemented measurement techniques.

In short, there is no industry consensus on the optimum manufacturing route – in terms of material composition, chamber geometry, and heat and surface treatment – to deliver XHV systems with ultralow outgassing rates.

Cooperate to accumulate

That could be about to change, however, thanks to a collaboration between Anderson Dahlen – Applied Vacuum Division, a specialist US supplier of ultrahigh-vacuum (UHV) and XHV systems to research and industry, and scientists at the National Institute of Standards and Technology (NIST), the US national measurement laboratory. Their work-in-progress study, formalized under a US government Cooperative Research and Development Agreement (CRADA), aims to evaluate the effectiveness of a range of materials and processing options in achieving ultralow outgassing rates in XHV chambers.

“Obtaining really low vacuum is a fight between pumping, or our ability to remove gas from a vacuum system, versus outgassing from the materials in the vacuum chamber or from the vacuum chamber itself,” explains Jim Fedchak, who heads up the outgassing studies within NIST’s Physical Measurement Laboratory. “Getting chambers made from ultralow outgassing materials is critical for scientists and industry engineers who depend on UHV or XHV environments.”

What’s more, the benefits are not just restricted to technical performance. For large vacuum systems, low outgassing rates mean that fewer pumps are required, with the potential to yield big savings on upfront capital outlay and ongoing operational expenditure.

All of which equates to significant commercial differentiation if you happen to be a supplier of XHV technology, claims Ben Bowers, regional sales manager for Anderson Dahlen – Applied Vacuum Division. “Despite the fact that we have many very happy repeat customers for our XHV products, they don’t publish data about the outgassing performance of their systems. We’re looking for independent validation of our XHV credentials, so who better to work with on that than NIST.”

Standardize and compare

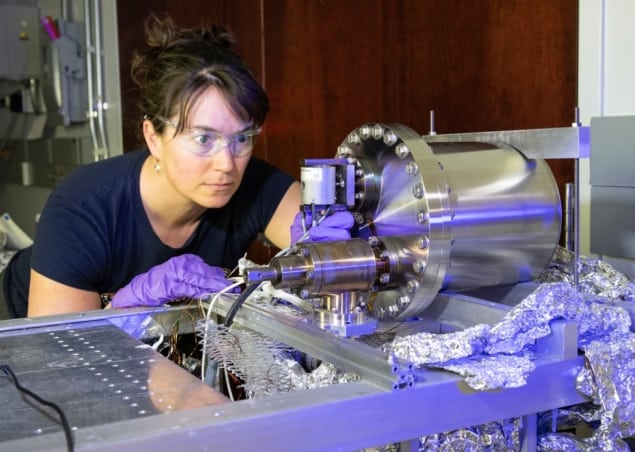

As the industry partner in the CRADA, Anderson Dahlen supplied NIST with seven identical UHV or XHV-specified test chambers – all of which have the same size and geometry. Using chambers of the same geometry enables a better comparison of outgassing rates, which are measured using spinning rotor gauges in a custom, computer-controlled manifold that was developed by NIST to enable temperature-dependent studies of outgassing.

Although their geometry is uniform, the test chambers are constructed from five different metals: titanium, aluminium, 304L stainless steel, 316L stainless steel and 316LN electroslag remelt (ESR) stainless steel (a high-specification steel that’s refined to remove impurities). “The most commonly used material for vacuum chambers is 304L stainless steel, which is also one of the most commonly used stainless steels,” explains Fedchak. “For XHV, we either require special treatments of the stainless steel or a different material altogether.”

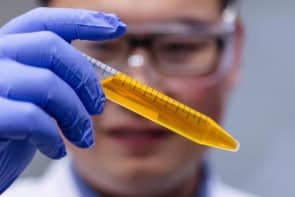

With this in mind, Anderson Dahlen handed over five of the test chambers with no heat/surface treatment prior to outgassing evaluation at NIST, while the two additional chambers – one made from 316L stainless steel, the other from 316LN-ESR – were vacuum-fired at temperatures above 950 °C.

“We heat the chambers north of 950 °C in a vacuum for an extended timeframe – basically driving the hydrogen out via heat followed by a controlled cool-down,” says Bowers.

While the outgassing studies at NIST are still ongoing, several trends are emerging. Early results indicate that aluminium, titanium and vacuum-fired 316L stainless steel all offer XHV levels of outgassing, reducing outgassing by potentially significant amounts compared to standard 304L stainless steel. Perhaps more surprisingly, the vacuum-fired ESR steel — currently the XHV material of choice for several big-science projects — appears to offer no outgassing advantage over 316L stainless steel.

Once confirmed, these findings will be detailed in upcoming journal publications. As a next step, the team plans to electropolish and air-bake the two XHV-processed chambers to see how these additional treatments affect outgassing behavior.

“This research breaks new ground,” claims Bowers. “No one has ever done this kind of comparative outgassing study on all of these materials before under standardized conditions.”

Bowers adds: “We were willing to expose ourselves here – and specifically our belief that stainless steel is just as good as titanium and aluminium for XHV applications. Commercially, we’re looking forward to getting the proof out there when these results are published formally in a scientific journal.”

Meanwhile, Fedchak points out that the outgassing studies are yielding pay-offs for NIST’s wider standards effort in the XHV regime. “NIST is interested in creating vacuum pressure standards that operate in the UHV and XHV,” he explains. “We are currently creating the cold-atom vacuum standard (CAVS), which will be a both a primary standard and sensor operating in the UHV and XHV. Materials with the best outgassing rates are excellent candidates to be used for the CAVS.”

He concludes: “The portable version of CAVS will provide a ‘drop-in’ substitute for existing vacuum gauges, allowing accurate measurement of vacuum even at the lowest levels—levels which are becoming more and more important in areas such as quantum information science.”

- Anderson Dahlen – Applied Vacuum Division will be exhibiting on booth 508 at the American Physical Society (APS) March Meeting from 4-7 March at the Boston Convention and Exhibition Center.

Decisions, decisions: which XHV material?

Ben Bowers, regional sales manager for Anderson Dahlen – Applied Vacuum Division, talked to Physics World about the commercial pros, cons and trade-offs associated with the various material options for UHV and XHV applications. Here is his summary take:

- 316L stainless steel is easily acquired in all sizes of sheet metal, plate and bar. Most manufacturing companies are tooled to machine 316L, which is also a very “weldable” material for UHV/XHV applications. Price-wise, 316L is on a par with aluminium and less expensive versus titanium.

- Aluminium is difficult to weld for UHV/XHV applications owing to the large heat zone during welding. Aluminium also requires the use of bimetal flanges (i.e. explosion-bonded aluminium to stainless-steel or titanium), mainly because aluminium knife-edges are soft and will deform or fail to seal properly as users open and close the vacuum chamber. However, aluminium is a magnetically inert material – a critical feature for some big-science experiments.

- Titanium is a lot more expensive when compared with 316L and aluminium. It’s also harder to machine and not as easy to acquire in the same assortment of material sizes. Furthermore, welding titanium for UHV/XHV applications requires a completely oxygen-free environment – which means that the manufacturer either needs a glovebox or heavy inert-gas purge of the material while welding. An added complication is titanium’s coefficient of thermal expansion, which is nearly half that of stainless steel. This means there are potential sealing issues when instruments are attached to the vacuum chamber with stainless-steel flanges – such as when the chamber is baked during operation. As per aluminium, titanium is better than stainless steel if users need a magnetically inert material.

“Ultimately,” Bowers concludes, “it’s all about customer choice. Tell us which route you’d like to go and we’ll build it.”