“Gas marbles” have been created by encapsulating a bubble of gas within a shell of tiny plastic particles. Developed by Yousra Timounay and colleagues at the Université Paris-Est (UPE) in France, the beads of gas could be used for isolating toxic gases or stabilizing foams.

The work by Timounay and team takes inspiration from “liquid marbles”, which were developed in 2001 by Pascale Aussillous and Davide Quéré from the Collège de France. Aussillous and Quéré had added hydrophobic powder to water droplets, thereby spontaneously creating balls of liquid securely held within water-repellent shells. The surface tension and incompressibility of the liquid allows the marbles to maintain their shape, and they can bounce and roll across surfaces without leaking.

Like soap bubbles

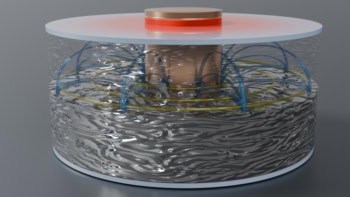

Now, the UPE researchers have created the gas version with a method similar to making bubbles with a soap solution and wire hoop. They carefully spread polystyrene microspheres over the surface of an organic compound solution (sodium dodecyl sulphate), where the spheres then floated in a closely packed formation. The team then submerged a rectangular wire frame (with sides roughly 1 cm long) in the solution.

Gently lifting the frame out creates a film of microspheres, just like on a wand for blowing soap bubbles. When the lift-out reaches a certain point, the film folds in on itself and detaches to form a gas marble that drops back into the liquid, automatically moving to the edge of the liquid’s surface. The marble – typically 5 mm in diameter – can then simply be scooped out. The researchers found that using larger microspheres (diameter 560 µm) and larger wire frames made it easier to create the marbles. “The full mechanism of gas-marble creation is not fully understood for the moment, but their creation is reproducible,” says team member Florence Rouyer.

Robust rollers

The resulting marble, presented in Physical Review Letters, consists of atmospheric gas constrained within a shell of closely packed wet microspheres. The spheres are stuck to their neighbours by the surface tension of a liquid meniscus. This microsphere-liquid “skin” is particularly strong – so much so that the team was able to alter the internal pressure using a syringe that could puncture the shell but not rupture it. The marble could then withstand a 10-fold pressure increase or decrease while maintaining a spherical shape with no volume change, before bursting or collapsing. “The structures are robust enough to hold and roll in your hand,” Rouyer says, “as long as your hands are clean, and you don’t press too hard.” Upon breaking up, the microspheres can be reused to make more marbles.

Timounay, who is now at Syracuse University in the US, and colleagues envisage that the gas marbles could have applications in stabilizing foams and emulsions. While they could also be used to store gases, their usefulness will depend on how easily said gas diffuses through the skin and whether the shells fall apart when the liquid evaporates.