By leveraging innovations in ultrastable lasers, accurate phase detection and timing synchronization, Menlo Systems’ femtosecond fibre lasers provide a core enabling technology for large-scale research facilities and industry applications

Femtosecond fibre lasers are all about versatility. With ultrashort pulse durations of just tens of femtoseconds (in the 10—15 s regime), and with different models covering visible through mid-infrared wavelengths, these compact, robust and reliable rare-earth-doped fibre sources have carved out diverse applications across science and industry – from additive manufacturing to molecular “fingerprinting”, from nanoscale spectroscopy to timing distribution in particle accelerators.

Now German precision photonics specialist Menlo Systems, a leading developer and supplier of femtosecond fibre lasers, is taking that versatility to another level. The manufacturer traces its origins two decades ago to the development and subsequent commercialization of optical frequency-comb technology (an invention for which Menlo’s co-founder, Theodor Hänsch, was a joint recipient of the 2005 Nobel Prize for Physics). Today, those optical frequency combs are routinely employed in fields as diverse as time and frequency metrology, spectroscopy, optical communications and fundamental physics.

In the course of its evolution, Menlo Systems has maintained something of a balancing act. On the one hand, the company has built its commercial success around high-precision and customized optical solutions for scientific customers all over the world – whether that’s smaller research groups or large-scale facilities like CERN in Geneva and the SACLA free-electron laser in Japan. At the same time, the manufacturer has forged long-term relationships with OEM industry customers, understanding their problems and gathering technical requirements to inform product development across the Menlo technology portfolio.

Those industry customers, for their part, are seeking femtosecond fibre laser systems that deliver against their core metrics – reliability, robustness, footprint, cost:performance ratio and the like – while scientific customers put the focus on parameters like superior pulse-to-pulse stability, lowest relative-intensity noise and excellent beam quality. For the latter, the dialogue with Menlo’s product development team is crucial and necessitates an extended commitment from vendor and research customer, often running over many months or even years (see “Overcoming time delays with photonics”, below).

“The process involves mutual learning – usually in a research setting – and iteration of technology solutions in close collaboration with the scientific customer,” explains Christian Mauser, product manager for femtosecond fibre lasers at Menlo Systems.

A novel concept for better lasers

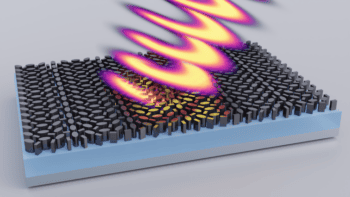

To support the diverse functional requirements for its femtosecond fibre lasers – whether in fundamental science, OEM industry applications or even space-based instrumentation – Menlo Systems developed its own mode-locking technology, based on an all polarization-maintaining-fibre design with no lifetime-limiting components. The key building block is a fibre oscillator that exploits Menlo’s patented “Figure 9” mode-locking technology – a robust optical set-up that combines simple, compact and reliable operation to yield several advantages versus other mode-locking approaches.

Our all-fibre mode-locking technology delivers outstanding performance, even in harsh environments.

Christian Mauser, Menlo Systems

“Our all-fibre mode-locking technology delivers outstanding performance, even in harsh environments,” explains Mauser. As a result, Menlo’s fibre lasers are suitable for portable operation in industrial manufacturing applications, while the excellent laser parameters give research users the reliability they need in a variety of settings – from imaging studies in neuroscience to next-generation materials microprocessing.

Equally important is the versatility of Menlo’s femtosecond fibre lasers. For starters, the timing jitter of the lasers’ output pulses is extremely low (in the attosecond and low femtosecond range), a feature that allows for creation of a timing master signal for precise coordination within a complex interplay of processes and events – for example, experiments at accelerator facilities or geodetic observatories. Further, Menlo’s proprietary intracavity actuators enable a particularly low phase-noise level over a wide range of laser repetition rates. “This is critical in applications with stabilized lasers, such as the interrogation of optical transitions in atomic clocks,” says Mauser.

Notably, all of these capabilities can be transferred to other wavelength regions (from 500 nm to 15 microns) via nonlinear frequency-conversion processes. Given Menlo’s vertically integrated structure, Mauser and his colleagues are also able to provide synchronization of the lasers to an external reference in a master–slave configuration, with fixed or tunable repetition rate. The master might be another laser, a hydrogen maser, or some type of RF signal.

Mauser adds: “It’s worth noting that other laser companies use our femtosecond fibre seed lasers and synchronization electronics to build their own laser systems. For the ‘drift-free’ distribution of timing signals, we offer all the necessary technologies – including stabilized fibre links, cross-correlators or balanced photodetectors – to ensure a timing precision of a few fs over distances reaching nearly 1 km.”

Overcoming timing delays with photonics

Scientists, it seems, are able to bend time to their will in at least some respects using the Timing Distribution and Synchronization System (TDS) from Menlo Systems. Built around a femtosecond optical pulse source – an optical femtosecond oscillator using an erbium-doped fibre in Menlo’s “Figure 9” design – the TDS distributes a master RF or optical reference “clock” throughout a large-scale research facility with minimal added phase noise and drift (<10 fs rms).

“Timing distribution gets really challenging really quickly if you want high accuracy,” explains Pablo Dominguez, TDS product manager at Menlo. “My role is to enable that synchronization and make it work 24/7 without operator intervention. Instabilities over days and weeks shall be of the order of a few femtoseconds, whether that’s in a particle accelerator or free-electron laser facility, a radio-telescope array or a geodetic observatory.”

Menlo’s TDS system was originally developed for pump-probe experiments in linear accelerators, though other applications are now emerging. One of Menlo’s flagship TDS customers is the Geodetic Observatory Wettzell, a geosciences research centre in Bavaria that’s engaged in fundamental studies of continental drift, sea-level changes and Earth’s gravitational field, as well as a range of reference measurements to support satellite navigation, geological surveys and mapping.

“I’ve been working closely with scientists at Wettzell for several years,” says Dominguez. “They need to fix and share a common reference clock, with sub-10 fs stability, across multiple experiments and observation stations over a range of several kilometres.”

Right now, the Wettzell team needs mathematical postprocessing to correct for temporal instabilities in the obervatory’s range of geodetic measurements – an unwanted source of complexity and potential distortion that TDS will address. “By fixing time in the femtosecond regime across multiple experiments,” notes Dominguez, “Wettzell will ultimately be able to measure distances between satellites, the Moon and Earth with an accuracy of tens of microns – a three orders of magnitude enhancement on what’s feasible today.”

The cornerstone of the Wettzell TDS is a mode-locked fibre laser – the optical master oscillator – which is synchronized to a low-noise RF oscillator to obtain optimum phase-noise performance, both close to and far away from the carrier frequency. The clock signal from the laser is amplified and split into the required number of ports prior to fibre-optic transmission across the facility to remotely synchronize other lasers or RF systems.

Much of the complexity of the TDS set-up lies in the active compensation and control of each fibre link, with path-length instabilities (typically of the order of several ps, corresponding to a few mm) addressed using Menlo’s high-stability phase detectors and ultrafast actuators (thus achieving sub-10 fs accuracy, corresponding to a few microns).

Dominguez concludes: “We build everything ourselves – the laser system, RF generator, optical and electronic subsystems – so we can be certain about quality, reliability and efficient system integration. Equally, we can also offer customization if the end-user wants modifications versus our off-the-shelf systems.”

Those modifications may include one to several RF outputs synchronized with the TDS, low-noise pulse-per-second (PPS) signals and additional output ports with custom wavelengths. “The form factor can also be adapted to the customer needs,” Dominguez adds, “since our devices must fit into unique locations like the cone-head of a radio-telescope.”